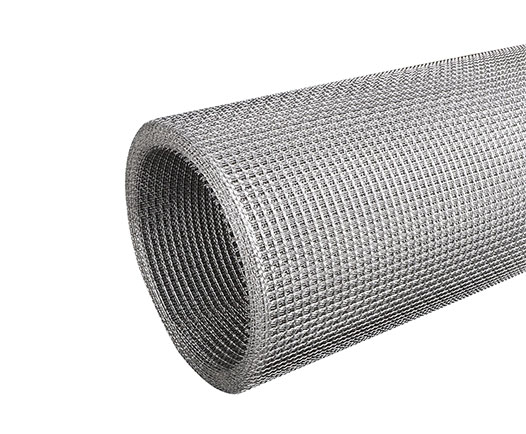

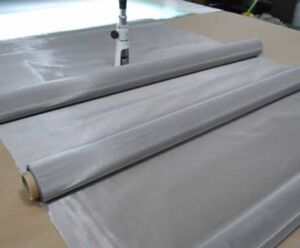

Crimped Wire Mesh is made by stainless steel wire and other alloy metal wires, something like: Pure nickel, Copper, Monel, Inconel, Hatelloy, FeGrAl, etc.

Weaving Patterns: Weaving after crimping.

This kind of wire mesh is identified from a wire crimped only in the points of intersection, before weaving. Crimped wire mesh is only made on request and the wire used may be round or square.

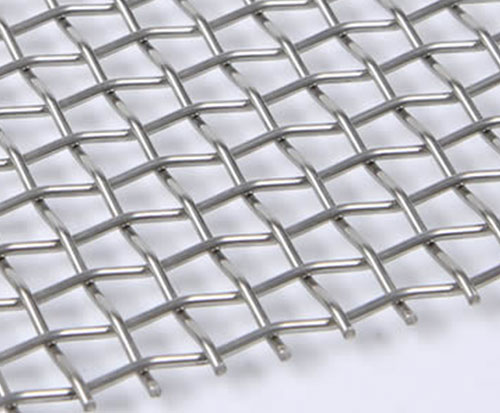

Product Features:

Crimped woven wire mesh offers great dimensional strength and stability, great resistance to abrasion, uniform openings and excellent anti-corrosion. It is usually used as quarry screen in mine, quarry and other industrial fields as sieving, grading and separating screening materials.

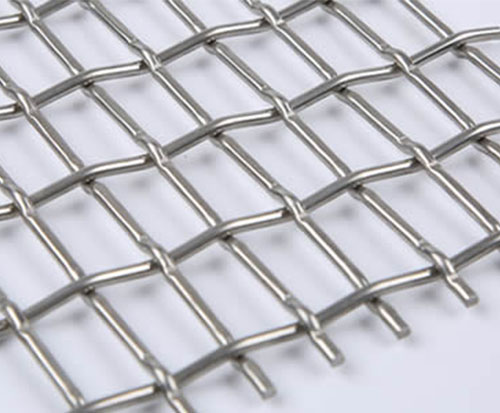

Basic parameters:

Aperture width: 10 – 120mm in the case of multi-notch meshes and 4 – 40mm in the case of single-notch meshes.

Wire diameter: 1.0 – 5.5mm.

Mesh width: up to 2000mm.

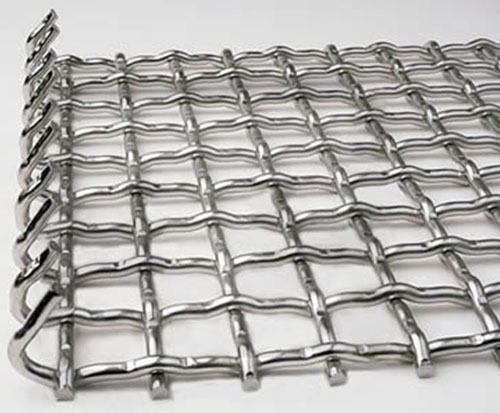

| Crimped Wire Mesh | |||||

| Wire Gauge SWG |

Wire Diameter (mm) |

Mesh/Inch | Aperture (mm) |

Weight (kg/m2) |

|

| 14 | 2.0 | 21 | 1 | 4.2 | |

| 8 | 4.05 | 18 | 1 | 15 | |

| 25 | 0.50 | 20 | 0.61 | 2.6 | |

| 23 | 0.61 | 18 | 0.8 | 3.4 | |

| 24 | 0.55 | 16 | 0.1 | 2.5 | |

| 24 | 0.55 | 14 | 0.12 | 4 | |

| 22 | 0.71 | 12 | 0.14 | 2.94 | |

| 19 | 1 | 2.3 | 0.18 | 1.45 | |

| 6 | 4.8 | 1.2 | 2 | 20 | |

| 6 | 4.8 | 1 | 2 | 20 | |

| 6 | 4.8 | 0.7 | 3 | 14 | |

| 14 | 2.0 | 5.08 | 0.3 | 12 | |

| 14 | 2.0 | 2.1 | 1 | 2.5 | |

| 14 | 2.0 | 3.6 | 1.5 | 1.9 | |